STRUCTURE STEEL FABRICATION

A.K.K. Engineering is specialized in structure steel fabrication and installation of industrial and commercial buildings. Our company is now a one-stop structure steel fabrication service provider with complete process capabilities ranging from design, detailing, fabrication, blasting, painting, testing and installation. Our current monthly production output is about 1,000-1,500 tons in workshop.

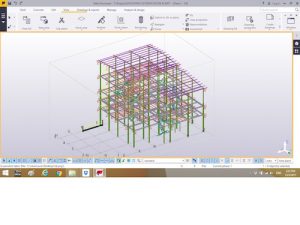

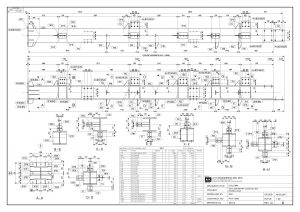

Design and Structure Steel Detailing

Our Engineering Team is able to produce design steel structure framed building based on technical input from our client. With the structural design approved, our steel detailer uses TEKLA Structure software to generate shop drawings with cutting plan to facilitate the fabrication process.

|

|

|

Steel Structure Fabrication

A.K.K. Engineering has invested in high tech CNC machineries to increase production efficiency, productivity and accuracy in structural steel products fabrication.

A.K.K Engineering owns a CNC Beam Drilling cum Band Saw production line, a CNC Plate Drilling machine, a CNC Plasma and Oxy-cutting machine which work and integrate seamlessly with TEKLA produced shop drawings.

|

|

|

Shot Blast and Painting Works

A.K.K. Engineering also owned a Auto Shot Blasting machine in workshop. The machine can achieve Sa 2.5 surface preparation with monthly production capacity of 1,500 – 3,000 tons. We also have in-house painting specialist team to ensure top blast and paint quality in the market.

|

|

|

|

|

|

Steel Structure Installation Works

A.K.K. Engineering is positioning itself as a one-stop solution provider for structural steel fabrication and installation. We have our own installation team and equipment to complete construction projects at site. We have proven track record in oil refinery plant, chemical plant, pipe rack system, warehouse and other industries. We also utilize TEKLA BIM (Building Information Modeling) software at site to assist the installation works.

|

|

|